Multi-shift, large forklift fleets move too quickly for traditional maintenance approaches to keep up with equipment demands.

Regularly scheduled maintenance activities help identify and address potential issues before they escalate into costly breakdowns or failures, leading to minimized disruptions in production and improved safety for personnel.

Does this sound like you?

Fighting a labor retention battle?

Annual turnover rates for manufacturing often exceed 30%, and nearly half of all employers struggle to retain workers in critical roles like maintenance.

Falling short of completing PMs consistently and reliably?

One third of facilities dedicate 30+ hours to scheduled maintenance, but 75% of their time is spent on urgent repairs.

Supplementing with high-cost rental equipment?

Rental equipment often cost double or more over the cost of forklift ownership.

Overlooking a boneyard of broken-down equipment?

The average cost of one hour of unplanned downtime is $300,000-500,000 for large facilities, leaving material handling equipment a low priority.

![]() It doesn't have to be this way!

It doesn't have to be this way! ![]()

Concentric solves the PRODUCTIVITY and DOWNTIME challenge with Dedicated On-Site Maintenance.

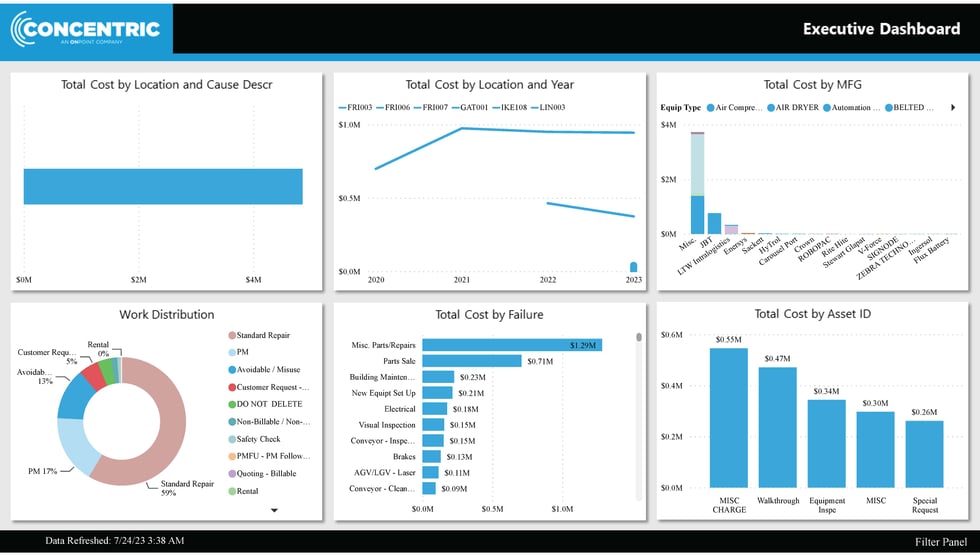

We provide full-fleet visibility and intelligence customized for you to take action.

25+

Years of Operation

200+

Dedicated On-Site Technicians

16K+

Assets Under Management

Dedicated on-site maintenance that enables you to move faster.

We Help Customers

✔ Improve pallet/each throughput 10% or more

✔ Strengthen PM completion to 99+%

✔ Reduce bottom line spending by 10+%

Our maintenance system is designed to serve all of your material handling equipment:

Customers We Serve

Manufacturers

Food, Beverage & Cold Storage

Warehouse & Distribution

3rd Party Logistics

What is the GuaranteedLIFT program?

Guaranteed Uptime at no-risk with a fixed monthly cost using your existing fleet

✓ Fixed monthly labor and power cost budget for 24-72 months

✓ On-site maintenance technician(s) to meet all your needs

✓ Solutions engineered and tailored for specific facilities and applications

✓ Quarterly business analysis reviews that include proactive maintenance/power recommendations

✓ FieldConnect reporting and analysis platform to drive fleet replacement cycles

✓ Spare or flex equipment for peak requirements or ageing fleets

✓ Guaranteed uptime

Transforming Maintenance Strategies for High-Velocity Distribution Facilities

by Cory Monroe, Regional Sales Director at Concentric

Cory Monroe, Regional Sales Director at Concentric, highlights the importance of adopting structured and thorough preventive maintenance strategies as warehouses and distribution centers grow.