Forklifts are a top expense for most high-velocity manufacturing and distribution companies, and the power that runs them equates to almost half of the cost. Plus, mis-sized or aging forklift batteries and chargers contribute further to downtime costs. Yet, this area is traditionally overlooked when it comes to radically improving your operators' experience and facility productivity.

Forklifts are a top expense for most high-velocity manufacturing and distribution companies, and the power that runs them equates to almost half of the cost. Plus, mis-sized or aging forklift batteries and chargers contribute further to downtime costs. Yet, this area is traditionally overlooked when it comes to radically improving your operators' experience and facility productivity.

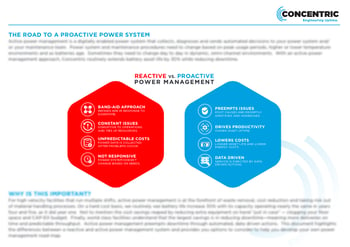

Why is such a crucial component for a company’s success so consistently disregarded? For most businesses, forklift power is handled as a highly reactive system, which means that issues are not addressed until there’s a problem. However, there’s a compelling case—including potential savings of up to 30%--to handling it as a proactive system.

To learn what proactive power can mean for your business, along with some concrete steps to migrate from reactive power, download our white paper, An Introduction to Proactive Forklift Power Management.

Download your free white paper now!